Frequently asked questions

Here you will find everything you need to know about our products at a glance. When it comes to selecting the right lubricant, adjusting the preload or cage materials – PM offers you competent advice and customised solutions. On the following pages, we have collected technical information about our products.

Click the categories below to browse the most frequently asked questions.

If you have very specific questions or cannot find the information you need in our collection, we are of course also available to help and advise you. Call us (Phone: +31 523 612 258) or send us an email at sales@PM.nl with your question.

General

Does PM have an ISO certification?

PM is ISO 9001:2015 certified. It means that our management system, manufacturing process, service and documentation procedures meet all the requirements for standardization and quality assurance. You can download the certificate here.

How do I receive a catalogue?

Download the latest release of our main product catalogue ‘Linear bearings and slides’. To receive a printed version, please send an e-mail to our sales support with your catalogue request in the language you prefer: English or German.

Where can I find 3D CAD Models?

The 3D CAD models can be found on this page: https://www.pm.nl/resources/3d-cad-models

Materials

Are linear guides and slides available in ceramic materials?

Yes, we offer anti-friction guides and slides in ceramic materials for non-magnetic or ultra-high vacuum environments. The available ceramics used are:

| Type | Material |

|---|---|

| Silicon nitride | Si3N4 |

| Aluminium oxide | Al2O3 |

| Zirconium dioxide | ZrO2 |

For the cage material, we offer stainless steel, POM, PEEK.

For more information about ceramic linear guides, please take a look at our product page.

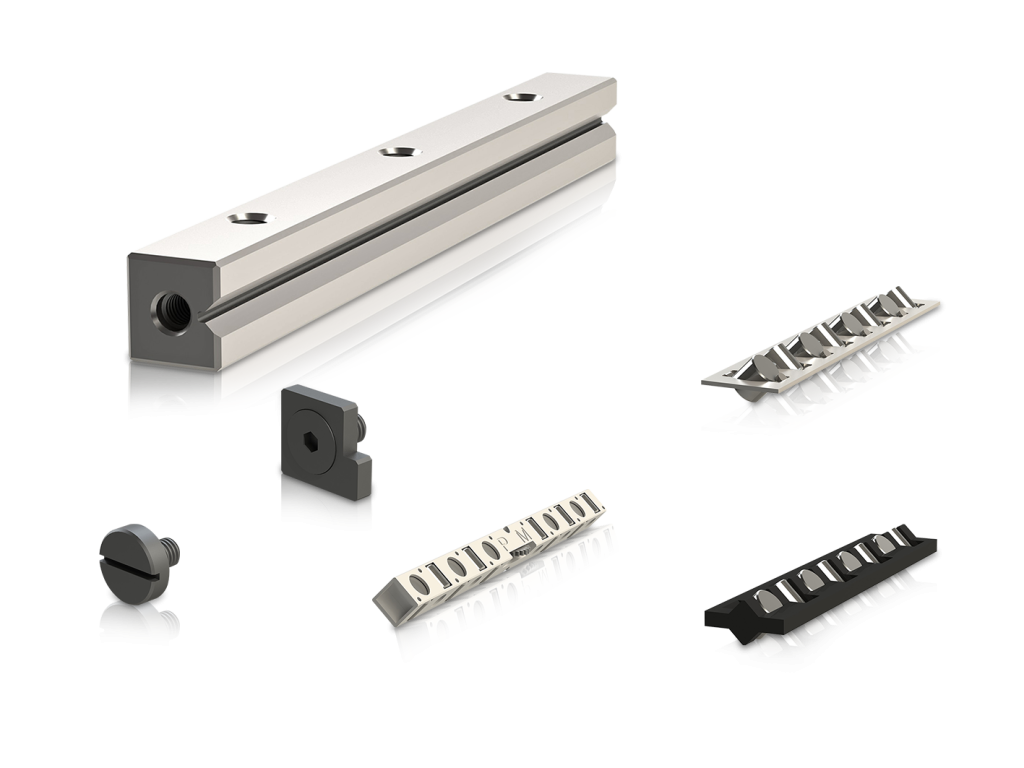

What materials are used for the (miniature) linear slides?

| Type | Material | Hardness HRC / Finishing |

|---|---|---|

| RT | Steel | Black oxide |

| RTA | Aluminium | Clear anodised |

| RTNG | Steel | Back oxide |

| RTS | Steel | Black oxide |

| PMM | 1.4034 | 54-57 |

| PMMR | 1.4034 | 54-57 |

| MSR | 1.4034 | 54-57 |

What materials are used for the cages?

| Cage type | Material |

|---|---|

| AA | 1.4301 |

| AL | Aluminium |

| KZR | POM |

| KKLK | POM |

| JJ | Brass |

| KRE | POM |

| KREV | PEEK |

| HW | Aluminium* |

* Needle roller cage type HW are optionally available in steel or brass cage body.

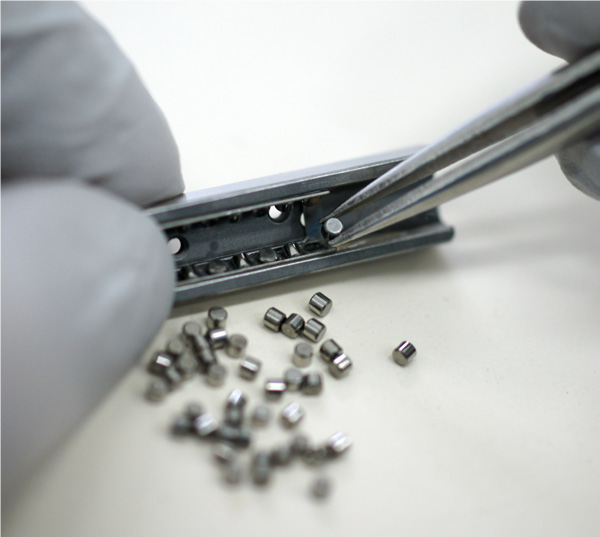

Cylindrical roller, ball and needle rollers are made from bearing steel 1.3505

Cage for anti-cage creep linear guides: material POM is used for cage type KRE and PEEK is used for cage type KREV.

There are cages available for vacuum and ultra-high vacuum applications. Please contact us for more information about these products.

Products

What are motion systems?

Motion systems are customised multi-axis motion platforms offering motion in X, Y, Z, theta, and tip/tilt. The system’s axes are integrated into the driving mechanisms and encoders and offer the “next level” in performance regarding accuracy and speed. Motion systems are delivered as plug-and-play with all electronics integrated.

Motion systems can offer both, long and short travel, or a combination. Drive mechanisms are typically linear motors for the long travel axes and ball screws, and piezo motors or voice coils for the short travel axes.

For linear guides, a combination is used for long travel, with recirculating guides or air-bearings. The shorter axes are typically designed with cross-roller guides for repeatable accuracy and smooth motion. The most common axes are X-and Y-axis, Z-axis, Theta-axis and Gonio-axis.

What are positioning stages?

Positioning stages or positioning systems include two or more axes providing precision motion in X, Y, Z, rotary or tip/tilt. The stages are built with linear tables, include the drive mechanisms, and are mounted on each other. In some designs the X and Y-axis are integrated, offering a monolithic design.

A monolithic design means that the top of the bottom axis and the base of the top axis are integrated into one piece. These stages are primarily used for high-precision applications. The linear bearing of choice is a type of crossed-roller or needle roller guide, as these provide extremely smooth and precise travel with high load ratings and rigidity.

Linear stages

Linear stages are constructed with a precision machined steel or aluminum top and base. They use high-precision linear guides such as cross roller guides and use different driving mechanisms (ball screw, linear motor, or piezo motor). For positioning feedback, they can be equipped with linear encoders. Linear tables offer single-axis straight-line motion with low friction and high precision.

Lubrication

Can I mix different types of lubricants?

During service-lubrication, it is important to check the compatibility of lubes. Mixing different oils or greases can reduce the performance of the linear bearings, resulting in reduced running smoothness, cage creep, and, at worst, damage to the linear guides.

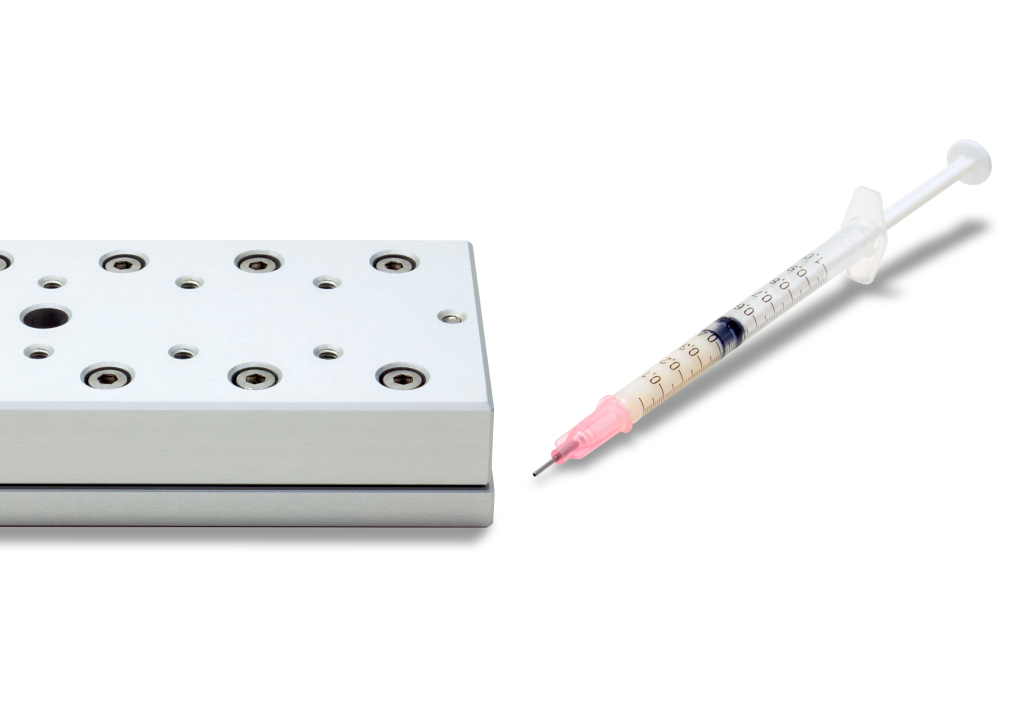

How do I apply lubrication to a linear guide?

First, start with cleaning the raceways with a clean cloth so that dirt, dust, and oil lubricant are removed. New lubrication can be applied using the gap between a pair of guideways. Just a very small amount is needed.

WANT TO KNOW MORE ABOUT OUR PRODUCTS?

Functional Always active

Preferences

Statistics

Marketing

Your catalogue download was successful

Also interested in our e-book?

The e-book is written for engineers and includes tips and tricks for the installation of linear guides

- Design tips from experts

- How to avoid commonly made mistakes

- 7 quick wins which will save you money

- Considerations on lubrication

- Clear illustrations

- Special edition written for the engineer