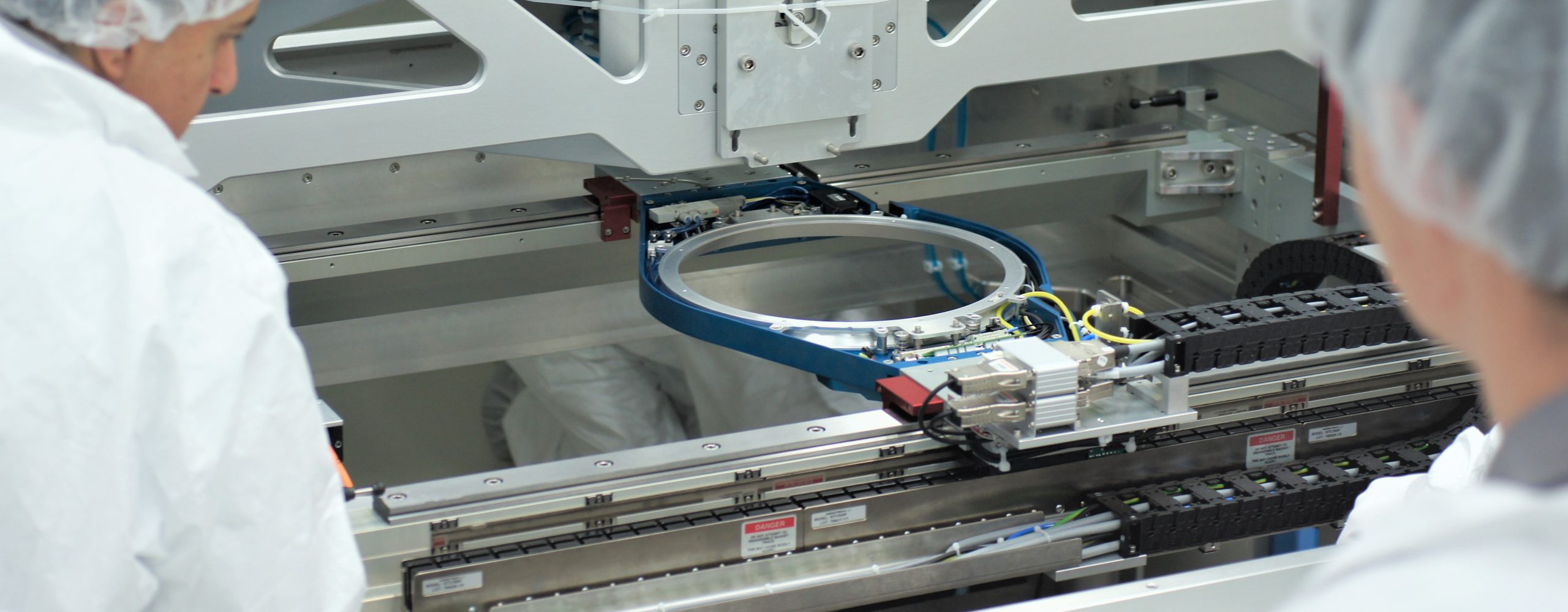

Customised 5-Axis Manipulator for cleanroom operation

Positioning stability, dynamics and precision are crucial in the field of in-line wafer inspection to maximise throughput. PM was requested to deliver a multi-axis positioning solution for smooth high-speed scanning and reliable operation. Our system engineers worked closely together with the customer to understand their project needs and achieve critical project goals.

Home » 5-Axis motion system

The challenges

- Achieve a lead time as low as possible;

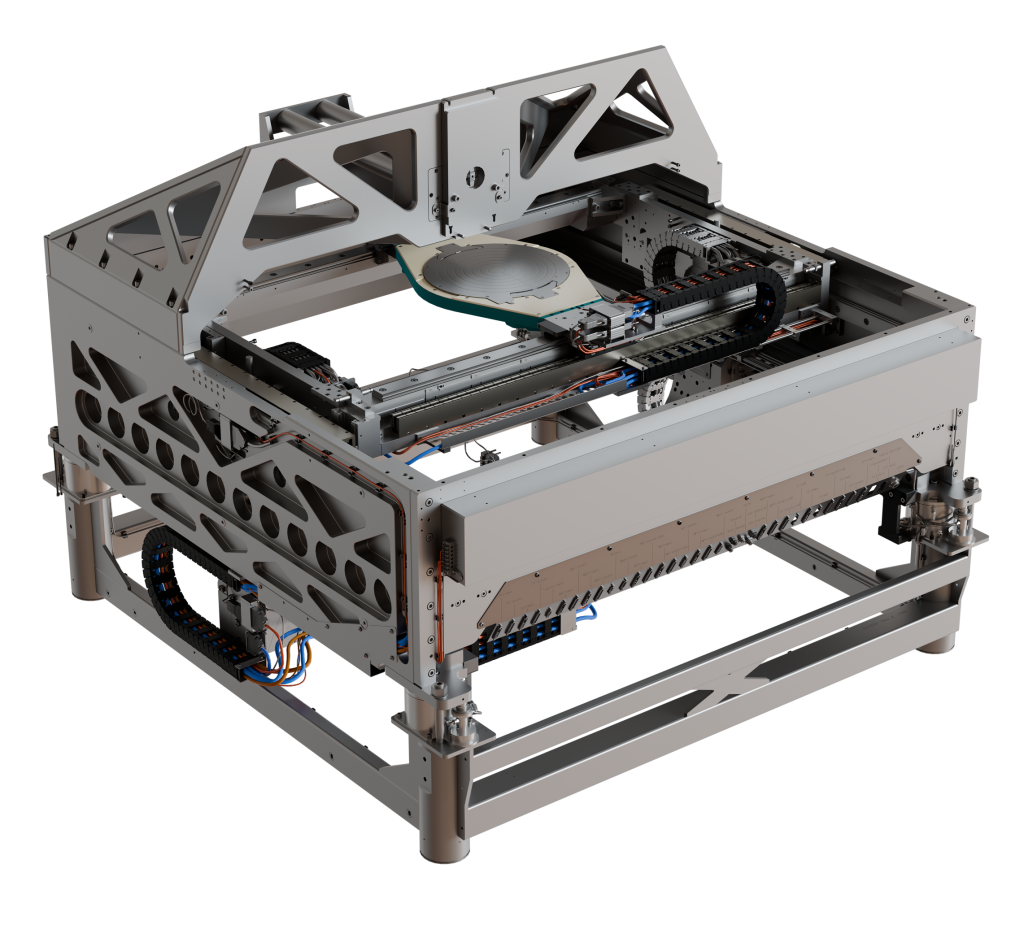

- Design of a fast and accurate wafer stage with a box frame to let x-ray beams pass;

- Make a modular design to improve upgradability;

- Cleanroom ISO class 6 compatible.

The application

For next-generation wafer inspection, the customer developed a non-contact, non-destructive measurement for inline front-end processes. The benefits range from stand-alone applications to fully automated inline measurements where every single wafer can be measured in production.

Results

- The first prototype was delivered within the time budget after the start of the project. This was a result of the fact that all company competences were combined. This allowed for great collaboration of the design, manufacturing and assembly processes;

- The box frame was optimised for stiffness to get a high as possible system bandwidth to make sure that settling times and accuracies were according to specification;

- The modular design allows for various configurations of the system. The system can either be equipped with 5 or 7 motion axis. Also, if needed, a vibration isolation system can be integrated.

Specifications

Stroke X-Y: 1050 mm x 490 mm

Speed: 1.4 m/s

Acceleration; 5 m/s2 for X-axis

Acceleration: 1 m/s2 for Y-axis

Stroke Z: 55 mm

Speed: 5 mm/sec

Drift: 50 nm in 20 sec

Dual driven linear motor / AC motor-driven

Cleanroom ISO class 6 compatible

Repeatability short term < 5 µm

Repeatability long term < 10 µm

Jitter 50 nm/20 sec. upper X-Y axis

Jitter 1 µm/20 sec. lower X-Y axis

Absolute accuracy < 15 µm

Linear guides XY combined with low profile ball recirculating units for long travel

Capabilities

PM offers unique in-house capabilities with extensive R&D and engineering service, application expertise for vacuum and ultra-high vacuum environments, in-house manufacturing, cleanroom assembly and various metrology and testing equipment. For more detailed information please see our competence page.

Reach Out to Our Specialists

Let’s talk about your application

Put our engineering and application know-how to work for you. Contact us today to discuss your high-performance motion system application.

Let’s talk.

Functional Always active

Preferences

Statistics

Marketing

Your download was successful

Request price and leadtime for this item

Your catalogue download was successful

Also interested in our e-book?

The e-book is written for engineers and includes tips and tricks for the installation of linear guides

- Design tips from experts

- How to avoid commonly made mistakes

- 7 quick wins which will save you money

- Considerations on lubrication

- Clear illustrations

- Special edition written for the engineer